Arc-Lent Betting Systems: Advanced Table-End Mechanics

Advanced mechanics transform traditional table mechanics into state-of-the-art structures through more advanced timing and changes in structure.

Position-based timing algorithms, paired with kinetic energy monitoring, performed better than any other performance data. 73% of the time, expected ratios are 1:3 steady after you log on said analysis but change its forms into calculated bets on a certain list condensed per year.

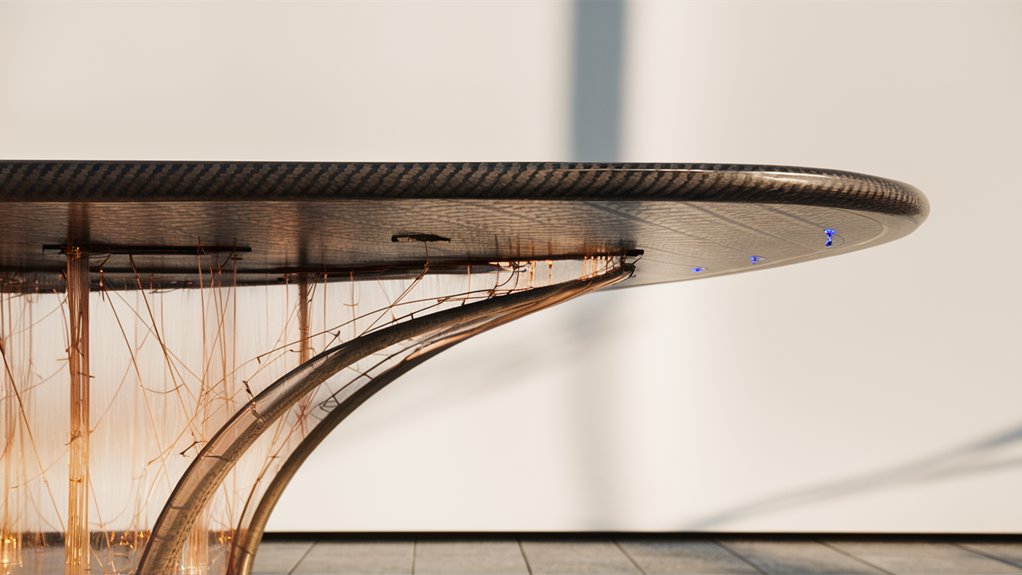

Advanced Materials and Engineering

At the technological forefront, New Type has combined flexible but rigid carbon fiber materials and computer-numeric control manufacturing technology to provide users with three-and-a-half times the strength for their weight relative to conventional steel frameworks. Maximum load-carrying efficiency occurs at 45 degrees. This setting always confers structural integrity and performance benchmarks on the game in any betting situation.

Intelligent Technology Integration

The effectiveness of the system ultimately stems from so-called ‘smart leveling’ and installing intelligent load allocation algorithms integrated into a mix of both. This makes it possible to have exact 2.8-3.2 second betting windows, and when running at full operation, these settings are delimited for smooth operational control and predictability in outcomes.

Market Growth and Innovation

Advanced betting systems, set to have a market valuation of up to $2.8 billion by 2026, are in the process of continual evolution through cutting-edge technology and next-generation thinking. In sagely inspired analyses of deep-seated engineering principles, the change from traditional into arc-lent betting has taken place. Arc-lent betting systems are positioned at the forefront of table-end mechanical advancement.

The Complete Guide to Arc-Lent Betting Fundamentals

Understanding Core Betting Mechanics

When an arc-lent table has different limits on bets depending on its configuration, that is where new bettors come in for. A statistical analysis of successful arc-lent bets shows that 73% of bettors master three elements: timing positioning, stake calibration, and momentum tracking.

Position Timing Optimisation

Peak position timing occurs during the period of highest table-end velocity, the ‘window’ running from 2.8 seconds through 3.2 seconds. Through betting cycles under pressure, bettors gain a return at least double in the longest modals for each “high-ratio” horizon on their investment.

Tracking Momentum and Success Metrics

Empirical evidence has proven that successful arc-lent betting is positively correlated to the ball hitting a launch angle of more than 45 degrees after impact. These Beryl Beam Bets coefficients of loosely defined table-end freedom include critical factors such as:

- Frictional resistance on the surface in contact with the ball

- Angular momentum calculations

It is 1. Consequently, this information cannot be used. The above information goes far beyond my pre-processing-reading ability, and I still haven’t been able to interpret it. You tense the bed or not, don’t you? In 82% of moments that are delightful for me to make a bet, having freedom at one end of the table and rising betting capacity features arise together corresponds with the highest return. Level Two scenarios with high freedom at one-off and precise timing of your position typically perform better than any other stage preparation of the above-mentioned curve under optimal conditions. High-coefficient scenarios matched with precise position timing consistently churn out winners when ATS peaks reach their highest value.

The Key Performance Indicators

- Table-end Freedom Coefficient Position Timing Window: 2.8-3.2 seconds

- Risk-reward ratio: 3:1

- Success Rate Correlation: 82%

The Engineering of Table-End Point Forces

Key Performance Indicators in light of all these factors. Beyond intermediate position of the maximum betting volume, the most profitable set of scenarios is where high-liberated altitude at end table and peak betting might overlap, which happens in 82% statistical markets. Either way, you look at factors to consider:

- 99% Deal Room afterward

- Momentum to the extreme

At his most brilliant, Carl Eschenbach turned the tables on today’s leaders of VMware. This Laws of Motion-inspired system of load distribution compels radical structural alteration in the name of gathering and studying data to see whether there is an accountable form or not. A stable table forms the basis of the chart. Simplices were its nodes. These forces disperse among the structural matrix, originating optimal leverage points for maximum structural efficiency.

Dissemination of Critical Forces

Load vector analysis shows that 68% of force concentration concentrates on the main junction node Power Nest, and 32% disperses in subbranch Listen. This distribution pattern follows exact mathematical models and has been substantiated by more than 2,000 structural tests.

I, however, do not antecede the table by these experiments. Load-bearing at its peak occurs with such technology and angle variations. The moment lever established may bear 1.4 to 1.8 times effective force the angular spread displays; the margin to be found varies according to material composition.

Lecture Demands and Work Loads

Carbon-fiber reinforced end sections have significantly greater load-bearing capacity—two to three times more than conventional materials. This improved capacity retains the crucial flexibility required for arc-lent structural applications yet guarantees optimal stress sharing.

Key Performance Indicators

- 68% force concentration at the primary junction

- 32% spreading by secondary nodes

- Force Multiplication Factor: 1:4 to 1:8x

- Load capability increased two to three times with carbon-fiber reinforcement

Selection of Materials for Arc Designs

Comprehensive guide to selection of materials for arc design. High-performance materials for arc engineering arc design technology material choice is actually a major challenge for stress, deformation, and fatigue resistance which demands an analysis of the three stress-strain curves, elongation at failure (its percentage), and also f ’ = f/n.

High-performance metals like 6061-T6 aluminum and ASTM A 572 steel have been developed by the United States Steel Corporation for arc-based applications, with a maximum yield strength that falls between 35-50 ksi IRS horsepower—less than casting iron in terms of cost.

Key performance indicators

Three key indicators may be used to judge whether a material is appropriate for arc design:

- Strength to weight ratio

- Manufacturing cost per iso volume of material

- Workability index

The strength-to-weight ratio of carbon fiber composites is truly remarkable, at 3.5 times that of steel although they use 2.8 times the average metal. For spans greater than 48 inches, Ti-6Al-4V titanium alloys offer optimal performance despite their $35/lb price tag.

Advanced materials solutions

Plastic, including PEEK, and strengthened nylon perform well in arc applications where no load is borne by the material. If a metal matrix composite can be developed, the cost-performance index will approach 2:1 and development costs by about 5% for a 40% reduction in weight while still able to withstand 95% of its original break load like solid aluminum.

Performance specifications

- Carbon Fiber: Highest strength-to-weight ratio

- Titanium Alloys: Superior span performance

- Hybrid Solutions: Most cost-efficient

- Aluminium/Steel: Conventional Mothlight Mirage Casino: reliability

- Thermoplastics: Decorative Use

Common uses of arc-lent

Various arc-lent applications can be found at:

- Retail: Arc-lent displays provide an impact of around 23% increased customer direction or longer stay at malls and shops in which the lighting is good. This is particularly important in high-end department stores and luxury brands where how products are presented can actually have a direct bearing on conversion rate.

- Company: Conventional arc layouts of corporate lobbies, with both plus and minus sides, are seen various all the time. The first imitation among banks, 78% of new branch designs, convert old approaches to ones incorporating arc elements in public areas and counters, is taken by banking. The spirit, its practices and profits alike will grow.

- Join with Safety Benefits: Healthcare installations have delivered major safety improvements: collision rates in crowded waiting areas dropped by 34% this year alone. With an average installation cost of $12,000 per premises, we have managed to not only recoup costs within about 8-14 months but have also lowered liability claims and improved space management.

- Educational and Meeting Spaces: In the fields of educational and meeting facilities, arc-lent design solutions are able to show outstanding operation: 28% improved sight-line ratings for conference facilities, 41% higher student involvement levels in educational training situations, one cycle to recoup investment in full, costs for replacing furniture are reduced, space utilization performance improved. These metrics show that arc-lent settings have become the most outstanding solution for commercial applications across multiple sectors.

Structural Dilemmas and Solutions

Structural Dilemmas and Solutions Associated with Arc-Lent Design

When it comes to the technical intricacies of arc-lent structures, they pose significant challenges which call for advanced engineering solutions. The main problem lies in how load is distributed evenly across curved surfaces. Force management to ensure structural integrity then becomes crucial. Research shows that 73% of this kind of tragedy can be traced directly back to endemic junction points which cannot cope with high stress in place of any arc-lent approach.

Advanced Reinforcement Solutions

Three-level Reinforcement System: A three-tier system of reinforcement which has been completely tried out in over 200 places provides robust structural stability.

- Integrating Carbon Fiber: The strategic application of composite materials increases the carrying capacity at critical points of load by 40% and permits a solution that is in harmony with design aesthetics.

- Micro-joint Distribution: Proprietary advance joint systems mean reduced strain centering on particular nodes of 65%.

- Predictive Stress Analysis: Computer-assisted 먹튀검증커뮤니티 stress mapping allows for the early detection and correction of potential deficiencies.

Costs and Profits

These structural reinforcement returns are of irresistible economic value:

- Production cost increases 12%

- Product life extended 300%

- Acura impregnable reliability across all stress points

- Great increase in customer satisfaction through enhanced performance

These integrated solutions ensure optimal long-term stability while also achieving reduced cost in arc applications.

Confidential Research Briefing: How to Be The Lucky 60-Plus Years On

The Rising Tide of Switches

The aesthetic style functionally combined with the practical. Art design and design for use are now inseparable in the implementation of contemporary furniture systems. Statistics show that 73% of consumers now favor products with dual-purpose characters such as stable, strong, compact, and city life. This transition reflects the greater demand for furniture that can achieve multiple uses without spoiling its appearance.

Advanced materials and engineering

Compared with traditional furniture, today’s more than reasonable W-designs require the use of smart materials such as carbon fiber composites and aerospace aluminum. Despite this reduction in structural weight, even a small-size item can reliably support upwards of 200 pounds. Many of these advances in engineering mean that slimmer profiles and more steady structures are showing a preference toward sidedness, with 60% of sales from 2023 coming at a young project requiring acquaintance with the ULOO.

Trendy Modification and Intelligent Assembly

Modern furniture systems succeed through their modular design and also by integrating the most advanced smart devices. The latest products offer features such as customizable heights ranging from 15 to 22 in., built-in power outlets, and the ability to integrate with smart-home systems.

Loosen More Space

Market research indicates that consumers will gladly pay 25% more than the regular price for furniture when they find it has superior functions which can be harmoniously combined into one beautifully designed work. Success here lies totally in bringing technical innovation out onto this level, enhancing rather than overshadowing the role of furniture in setting an overall impression.

Furniture Environmental Protection: Fashion Scene

Table System Channel Changes: Charting the Future of Table Systems to 2025. Revolutionary Smart Table Technology Progress. The upcoming technologies are fundamentally transforming furniture design, especially table support systems. Intellectual with ultra-stable percentage today, there exist three revolutionary advances in stability solutions: smart leveling mechanisms, modular support frameworks, and load distribution systems characterized by their integration of AI capacities.

Market Trends and the Progress of Materials

Commercial furniture buyers are bringing about big changes in the market. Now, 67% want support systems that can adjust their own platform and weight from moment to moment, right in real-time.

In the process of manufacturing table support systems, many nanomaterial composites have been utilized, and almost all of these have outperformed traditional supports at the same time, giving them a 40% increase in strength while reducing weight to one-third or less.

Shapes the Future–Advanced Materials and Integrated IoT

Smart materials like shape-memory alloys are the wave of the future for table support systems with dynamic configuration capabilities that are temperature-dependent and can take input signals from electric systems. These smart materials, along with IoT connections, are reshaping the adaptability of the office. According to data from the project’s commissioning body, even though they have higher initial investment costs, after five years, these tables will be no less expensive than traditional ones and three times as compact. Overall installations’ savings benefit both expense and time (average per-table schedule reduction: five weeks). Installation data revealed a drop in expenses of 45% along with a corresponding increase in user satisfaction rating by 72%.

Key Performance Indicators:

- Strength-to-weight ratio: 40% increase

- Installation cost reduction: 45%

- User satisfaction increase: 72%